The competitiveness of the industry over consistent and high-quality product with low price demand is increasing. To meet these demands, industry owners have begun utilizing various methods that can help them reach the higher position in the market. One such option is the introduction of automation which is slowly overtaking the role of traditional methods like mechanization processes. Automation has reduced the manual intervention in operating machines, thereby, increasing the overall productivity of the enterprise. A study by Statista suggests that the number of process automation devices has doubled in the past five years.

With technology automation, industries can attain higher accuracy, better quality and precision in the performance of different industrial processes. The term industrial automation refers to the use of various control devices like – PLC, PC, and PAC to replace human intervention by using logical programming commands and powerful machinery. This reduction in human involvement reduces any threat to human life and eliminates the chances of human error in production.

The Need For Industrial Automation

- For increasing productivity

Automation in manufacturing process plant improves the rate of production and provides better control over the process. It reduces the assembling time per product by increasing the rate of production.

- For improving product quality

Integrating different process with automation minimizes the production cycle’s time and efforts. This, in turn, results in reduced intervention of human resources. The investment of these resources can lead to improvement in the product’s quality.

- For reducing routine checks

With the reduction of human involvement, there are very less chances of any human error in production. This helps in reducing the number of routine checkups for the quality of the products.

- For raising safety levels

Technology automation in industries increases safety level for their personnel by substituting them with machines. Processes that pose a risk to human safety can be easily completed with the help of machines.

Different Levels of Automation Systems in Industries

- Field Level

This level consists of automation of field devices such as sensors and actuators. Sensors collect data on various parameters such as pressure, temperature, feeds and speed. They convert this data in the form of electrical signals and deliver it to the next level. The primary task of field devices is to transfer data of machines and processes it to a higher level of monitoring and analysis.

- Control Level

The field level consists of different automation systems that gather process parameters from multiple sensors. The controllers then drive the controlling components of the machine based on sensor signals.

- Supervision Level

In the supervision level, monitoring systems and automatic devices facilitate the adjustment and control functions of the process. It includes setting production targets, monitoring of various parameters, archiving essential data and setting start and shutdown function of the machine.

Various Types of Industrial Automation Systems

- Fixed Automation Systems

Fixed automation is employed to execute repetitive tasks for achieving higher production rates. Once employed, the automation process is hard to change according to the product design. It only increases the efficiency and production rate for a similar variety of production.

- Programmable Automation Systems

In this automation process, a variety of product and processing operation can be changed by the modification of control programs. This automation process is best for production where the product’s volume is medium. It becomes hard to reconfigure the system from a new product or sequence of various operations. These systems are mainly used in steel rolling mills, paper mills and industrial robots.

- Flexible Automation Systems

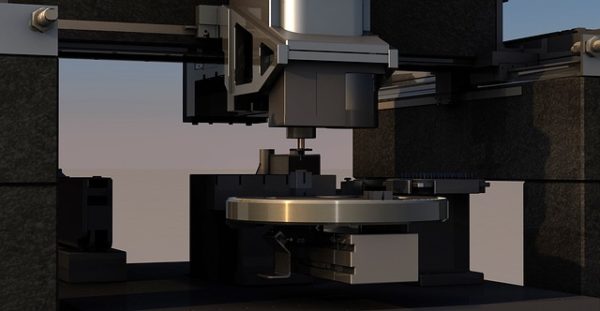

These systems provide auto-controlled equipment with the flexibility to change the design of the product. The changes are performed quickly through various commands provided in the form of codes which allow the production of several products at a time. CNC machines and Automatic Guided Vehicles are examples of flexible automation systems.

- AI Led Automation Systems

While the above-mentioned automation systems are efficient in working, new AI led automation systems are also being launched to reduce further human errors in business operations. These systems are adept in leveraging cognitive techniques to provided superior user experience, presenting real-time unified dashboards and better monitoring of the operations.

Industrial automation is the stepping stone for exceptional productivity standards of industries. The superior efficiency, improved designs and rigorous safety standards are only some of the benefits of technology automation. Implementation of software in various hardware will change the industry standards forever. Therefore, enterprises looking to thrive in this cut-throat competition should start investing in automation technology for better growth.

Gearfuse Technology, Science, Culture & More

Gearfuse Technology, Science, Culture & More